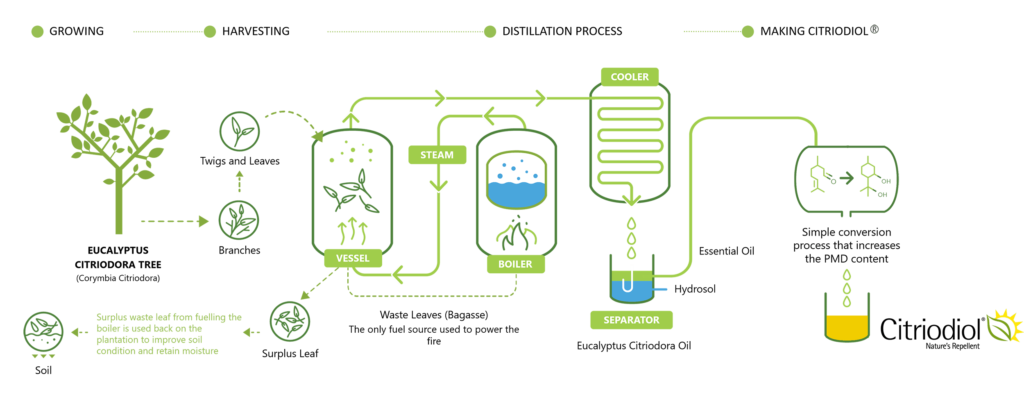

Growing the trees

Citrefine have strong, long established relationships with trusted production partners across the world. We pride ourselves on working with only the most sustainable and ethical suppliers and are actively involved in managing quality and production standards.

At all plantation sites:

- Seedlings are germinated locally before being planted and tendered by hand

- The soil is conditioned with lime on planting (and as required thereafter) to ensure optimum health and vitality of both the ground and the quality of the oil produced

- Excess waste leaf from the distillation process is used to further improve soil condition and help retain moisture

- Weeds may be controlled by running cattle in the plantation, which also fertilises the soil

- The trees and the oil are not genetically modified

Harvesting the leaves

As the demand for Citriodiol® increases, so do the number of trees planted and grown to produce our oil. These plantations are sustainably managed by skilled local partners and mindful harvesting techniques:

- Leaves and branches are harvested by hand from the trees by teams of local workers (both men and women)

- Branches are cut selectively from each tree during the harvesting process so that the trees can continue to grow and produce new leaves for many years

- Once the branches have been harvested, the twigs containing leaves are cut from the branches (these leaves and small twigs are steam distilled to produce Eucalyptus Citriodora oil)

- The number of harvests each year is adjusted to ensure the on-going health of the trees.

- During the 10-15 year life-span of each tree it will be cut to a stump (coppiced) and allowed to re-grow.

- At the end of its life it will be cut down and a new line of trees will be planted adjacent.

Distilling the oil

- Harvested twigs and leaves are placed in a large vessel, compressed and sealed

- Steam passes through the vessel distilling the oil from the leaves

- As the steam cools the water and oil separate and the oil is captured in drums

- A closed water system condenses the cooling steam and recirculates it for reuse

- Waste leaves (known as bagasse) and surplus twigs are used as fuel to fire the boiler which produces the steam, and excess bagasse is used to maintain the soil

- No other fuel is required to run the boiler and excess energy generated by the process may be used to run other equipment

Nothing is wasted

The trees that are cut down are specially treated for use as poles or sold to local businesses, with waste used as fuel and fertiliser

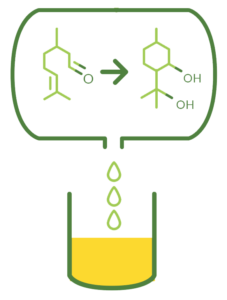

We convert the high citronellal content in the essential oil into the naturally occurring substance PMD (p-menthane-3,8-diol)

- In nature, as the oil found in the leaves of the Eucalyptus citriodora tree ages, the main constituent of the oil (citronellal) gradually turns into PMD (p-menthane-3,8-diol).

- Some PMD is found in the “young” oil, but only in small amounts. It is more difficult to distil the oil when it is more mature and because the PMD is central to the efficacy in repelling biting insects, Citrefine’s suppliers harvest the oil from leaves that are about 12-18 months old.

- This oil is supplied to Citrefine who use a simple manufacturing process to convert the citronellal to PMD.

The result is Citriodiol®, which contains an average of 71%* PMD and only a negligible amount of citronellal. The other naturally occurring minor components in the Eucalyptus citriodora oil remain largely unaffected by this process. (*min. 64%)

The result is Citriodiol®, which contains an average of 71%* PMD and only a negligible amount of citronellal. The other naturally occurring minor components in the Eucalyptus citriodora oil remain largely unaffected by this process. (*min. 64%)

In this way Citrefine is effectively mimicking nature’s own ageing process.

Scroll to top